JMC at CPhI 2022

JMC will be exhibiting at CPhI Worldwide 2022. This event is being held in Frankfurt, Germany from November 1-3. This is the first CPhI Worldwide show to be held in-person since the start of the COVID-19 pandemic. The JMC team is looking forward to reconnecting with customers from around the world.

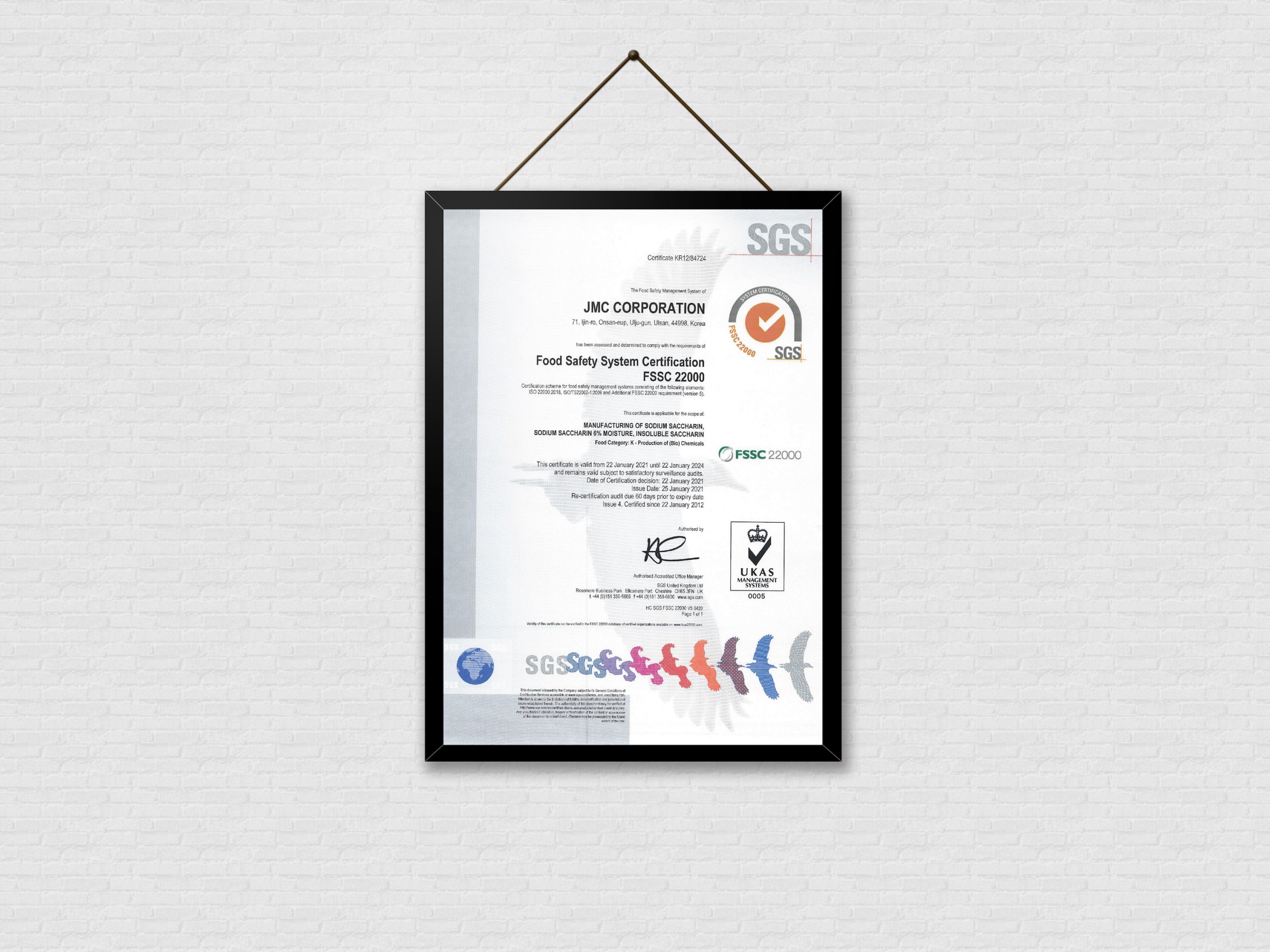

Throughout the pandemic, JMC’s factories have remained open at all times and production has continued without interuptions. This has enabled JMC to cement its reputation as a reliable supplier of the world’s highest quality saccharin.

For more information about CPhI Frankfurt, visit: https://www.cphi.com/europe/en/home.html

JMC partners can register to attend for free through their JMC Sales contact person.